Pneumatic Powder Transfer System

A pneumatic powder transfer system is a type of material handling system used to transport powdered or granular materials through pipelines using compressed air or gas. This system is commonly used in industries such as food processing, pharmaceuticals, chemicals, plastics, and mining for transferring materials like powders, granules, pellets, and flakes.

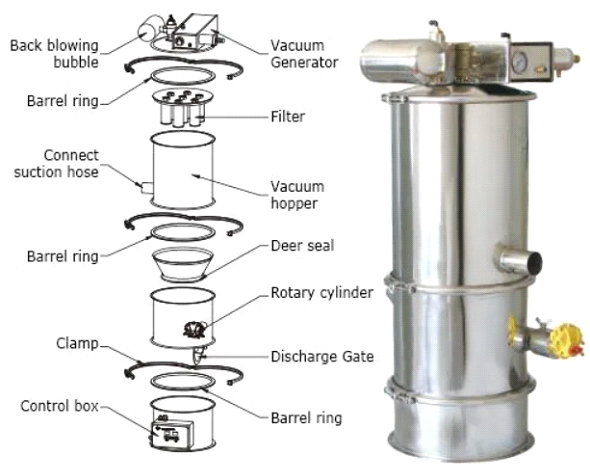

The key components of a pneumatic powder transfer system include:

- Material Source: This is where the powdered or granular material is stored, such as a silo, hopper, or storage bin.

- Pneumatic Conveying Pipeline: The pipeline is used to transport the material from the source to the destination. It is typically made of durable materials such as stainless steel or plastic to withstand the abrasive nature of some materials.

- Compressor: A compressor is used to generate compressed air or gas, which is then used to convey the material through the pipeline. The compressor must provide sufficient pressure and airflow to move the material effectively.

- Airlock or Feeder: An airlock or feeder is used to introduce the material into the pneumatic conveying system without allowing air to escape. It helps maintain the pressure inside the pipeline and ensures continuous material flow.

- Filters and Separators: Filters and separators are used to remove dust, debris, and contaminants from the conveyed material and the conveying air or gas. This helps maintain the cleanliness of the system and prevents blockages.

- Receiver or Destination: The receiver is where the material is discharged from the pneumatic conveying system. It can be a storage vessel, processing equipment, packaging machine, or another destination point.

The pneumatic powder transfer system operates by creating a high-velocity airstream that suspends and carries the powdered or granular material through the pipeline. The material is entrained in the airflow and transported to the desired destination with minimal degradation or loss.

Benefits of pneumatic powder transfer systems include:

- Efficient and hygienic material handling, particularly for sensitive or fragile materials.

- Dust-free operation, reducing environmental contamination and improving workplace safety.

- Flexibility to convey materials over long distances, around obstacles, and between multiple points.

- Automation capabilities for continuous and reliable material transfer.

- Easy integration with existing production processes and equipment.

Overall, pneumatic powder transfer systems offer a reliable and cost-effective solution for transporting powdered or granular materials in various industrial applications.